Egnergy

Egnergy's product offeringsStop detrimental moisture in your air before it causes damage!

Dew Point monitors and monitoring systemsDew Point Temperature is defined as the temperature at which condensation begins when air is cooled at a constant pressure

How does this apply to compressed air systems? When compressed air leaves the compressor it is saturated with water. This means that if the compressed air is cooled from the temperature it leaves the air compressor water will condense in the system. This is the theory of operation behind a refrigerated compressed air dryer. Cool the compressed air down to close to freezing to condense the moisture out of the air, then remove the moisture through a moisture separator and drain valve, then heat the air back up to ensure the pipes don't "sweat" in the plant.

Egnergy sells systems that constantly monitor the dew point in your system and send email notifications if dew point is out of specification.

- These dew point meters can be used in the following industries:

- Hospitals for instrument air

- Power Plants

- Petro Chemical facilities

- Refineries

- Industrial Manufacturing facilities

- Nitrogen Generation

How would you like to know you had a problem before you got the phone call from production that the lines were full of water?

Dew point monitors for compressed air and nitrogen with dew point down to -100 C

Air and nitrogen flow meters

Use these meters to measure and record the flow of your entire system or for point of use applications.

Compressed Air Flow Meters for measuring flow in pipes from 1/2" to 36"

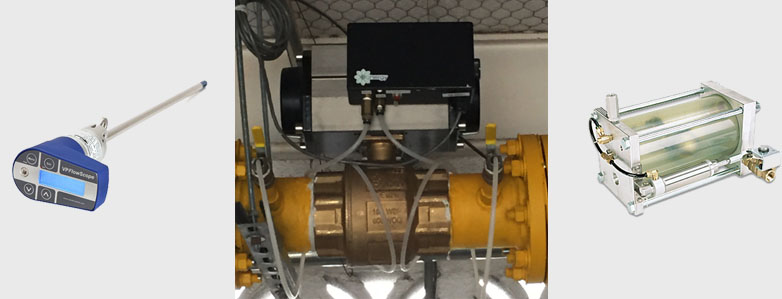

We represent two different types of compressed gas flow meters. The first is installed inline and comes in 3 sizes (1/2", 1", and 2") and are installed in the piping for the process being monitored. The second is an insertion type. The insertion type can be installed while the system is pressurized through a 1" ball valve in the compressed gas header with header sizes up to 36".

There are two types of insertion flow meters. One uses a thermal probe to measure flow and is not suitable for dirty oily air. The other is a differential pressure meter that can be used in oily and wet applications.

All flow meters are capable of monitoring flow, pressure and temperature and can output these measurements via modbus or 4-20 mA signal (when using the 4-20mA signal only one parameter can be measured). These meters are also available with a data logger integral to the meter so all you have to do is download the data and analyze it.

- These gas flow meters can be used in the following industries:

- Power Plants

- Petro Chemical facilities

- Refineries

- Industrial Manufacturing facilities

- Nitrogen Generation

- Steel Mills

Compressed air condensate management products

Get rid of your condensate and clean it up with these condensate management products from Egnergy

Compressed air condensate drains and oil water separators

The Compressed Air Condensate oil water separator utilizes multi-stage separations technology to clean up condensate streams to stay in compliance. In the first stage, the Sediment Chamber collects and prevents rust, dirt, and scale from migrating into the Main Reservoir. The second stage is the large Main Reservoir, which provides sufficient residence time to allow oil to coagulate and float to the surface. Next, the Pre-Adsorption Chamber removes the segment of oils that are still in solution or have migrated through. In the final stage, the Zeolite Media ensure that the condensate will meet or exceed the discharge limits.

Remove the condensate from your compressors, dryers, tanks and system low spots with our condensate drain valves.

Our no loss condensate drains can save you energy while providing the highest quality most reliable drain on the market. The no loss drain valve can have a return on investment of less than 6 months and the clear casing allows for easy visual verification of proper operation.

Compressed air system efficiency

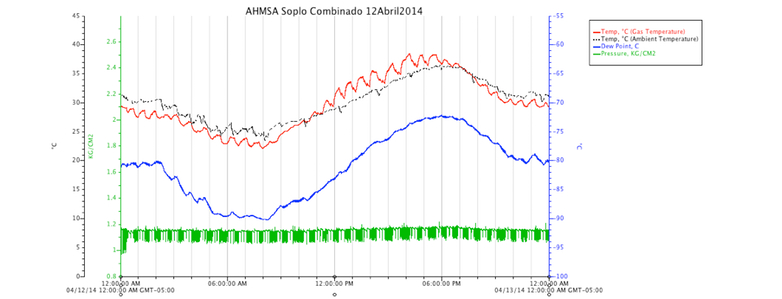

See a video of the Egnergy Efficiency Monitor in actionThis system was designed and installed by the engineers from Egnergy. It uses power transducers, pressure transducers, and a compressed air flow meter to continuously measure the efficiency of the compressed air system. The system operates at an average efficiency of 78% with a savings opportunity of $33K annually.

The monitor emails plant personnel with monthly cost of energy to operate compressed air system and average efficiency. There is also a live interface operators can log into from inside the companies local area network to watch the monitor in real time.

Egnergy can design and install a monitoring system similar to this one for your compressed air system. Prices range from $7,000 to $100,000 depending on system complexity and parameters monitored.